For many car enthusiasts, maintaining the flow of oil through their engine is essential for optimal performance. It’s no surprise then that oil hoses play a vital role in keeping your vehicle running at its best.

Oil hoses provide an important link between the various components within the engine and ensure that all parts are connected and working properly. But what exactly makes oil hoses so important? This article will explore why understanding the importance of oil hoses is key to achieving peak performance from your engine.

Well, look at how they work and how to maintain them properly to keep your car running smoothly for years to come. So buckle up and join us on our journey as we unravel the mysteries behind these critical components!

Understanding the Role of Oil Hoses in Engine Performance

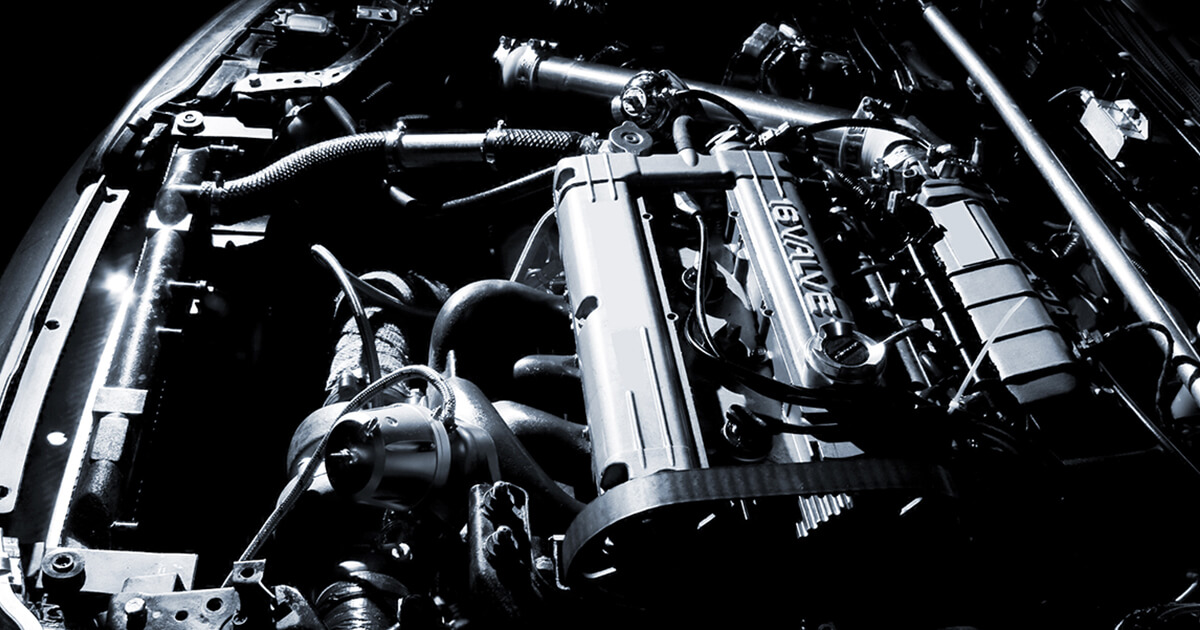

When it comes to engine performance, oil hoses play a major role. These components are responsible for transferring the lubricant from the engine block to its various parts such as cylinders and valves, keeping them running smoothly.

As they are constantly subjected to intense heat and pressure, oil hoses must be made of high-quality materials that can withstand these extreme conditions. Regular inspection and maintenance of oil hoses are essential to ensure optimal functioning.

Hose clamps should be checked regularly for any damage or signs of wear and tear; if any damage is found, the hose should be replaced immediately. Also, it’s important to make sure that all connections between different sections of the hose are secure so there are no leaks or weak spots along its length.

In addition, ensuring proper installation is key when it comes to maintaining flow through an oil hose system. All connections need to fit snugly together without being overly tight or loose; this will help prevent air bubbles from forming in the line which could interfere with normal operation over time.

It’s also important that all fittings have been securely tightened down so they do not come apart while under pressure during use. Finally, when replacing worn-out hoses or performing routine maintenance on existing ones, always use a quality product designed specifically for automotive applications rather than generic items intended for other purposes such as plumbing systems – this will help ensure maximum efficiency of your vehicle’s engine performance over time!

The Benefits of Properly Maintained Oil Hoses

Oil hoses are some of the most important components in an engine. They provide a conduit for oil to flow through, allowing parts of the engine to lubricate and cool properly.

As such, these hoses must remain in good working order at all times. When properly maintained, oil hoses can offer several key benefits.

Firstly, properly maintained oil hoses help reduce wear on internal engine components which can lead to significant cost savings over time. Oil hose maintenance also ensures that the right amount of lubricant is being delivered to critical areas within the engine while preventing leakage or contamination from outside particles that could harm its performance.

This helps maximize efficiency and extend the life expectancy of your vehicle’s vital components even further. Additionally, proper maintenance prevents damage caused by heat build-up due to inadequate cooling as well as corrosion brought on by age or exposure to certain chemicals like anti-freeze or gasoline vapors which may be present in high-temperature environments like garages with poor ventilation systems.

By conducting regular inspections and replacing worn-out parts when necessary you can ensure optimal performance without having to worry about potential long-term problems arising down the line!

Identifying Common Problems With Oil Hoses

Oil hoses are essential for proper engine performance, but unfortunately, they can wear down over time. Identifying common problems with oil hoses is key to maintaining the flow of an engine and ensuring its longevity.

Signs that your oil hose may need to be replaced include leaking, stiffening, or cracking along the length of the hose. Leaking around any fittings or clamps could also indicate a problem.

If left untreated it can lead to serious issues such as reduced efficiency and power output from your engine or even a complete failure if not addressed quickly enough. Additionally, age should also be taken into consideration when assessing whether an oil hose needs replacing; rubber wears out over time and becomes brittle so that it is no longer able to withstand high pressures and temperatures in the same way as when new.

While inspecting your oil hose you should look out for bulges due to improper installation which could cause them to burst at some point in future use. Keeping an eye on these common signs will help you ensure optimal performance from your vehicle’s engine by keeping all components functioning properly.

How to Extend the Life and Efficiency of Your Vehicles Oil Hose System

When it comes to keeping your vehicle running smoothly, oil hoses are an essential part of the engine performance. Over time and with continued use, these hoses can start to show signs of wear and tear which can reduce their efficiency or even cause them to fail.

To get the best out of your vehicle’s oil hose system and extend its life span, there are several simple steps you should take: First, check regularly for any visible cracks in the surface of the hose as this is often one of the first signs that it needs replacing. If you find any damage then replace the hose immediately as leaving it could lead to more serious issues further down the line.

Secondly, ensure that all fittings on oil hoses are securely fastened so they don’t become loose over time. This will help prevent leakage and other potential problems from developing due to faulty connections between parts.

It is also important to make sure that no air bubbles form in the lines as this could affect flow rates across different components within your engine system – something which must be avoided at all costs! Thirdly, keep track of when you last changed your oil filter and make sure that it is replaced according to manufacturer specifications (usually every 6 months). A clogged or blocked filter can restrict flow through vital parts such as cylinders leading ultimately lead reduced performance levels for your entire vehicle’s system if left unchecked.

Finally, keep a close eye on all levels related to fluid movement inside an engine such as coolant level or transmission liquid pressure – these should always remain at optimal levels for maximum efficiency from oil hoses. In addition, regular maintenance checks by certified technicians will help identify any underlying issues before they become major problems later down the line with regards to safety or otherwise!

Conclusion

Oil hoses are an essential component of any engine and play a crucial role in its performance. Without oil hoses, an engine would not be able to cool or lubricate itself properly, leading to premature wear and tear.

Regularly checking and replacing oil hoses can help prevent major issues from occurring in the future and keep your car running smoothly for years to come. By understanding how important it is to maintain the flow, you will be better equipped with knowledge on how best to protect your vehicle’s engine for long-term success.