For decades, cutting machines have revolutionized the manufacturing industry. From woodworking to metal fabrication, these powerful tools have made it easier and faster to create complex designs with precision accuracy.

Now, laser cutting technology has taken this process to a whole new level of efficiency and capability. In this article we will explore the incredible power of laser cutting machines and how they are pushing the boundaries of modern production capabilities.

Well discuss why they are becoming an increasingly popular choice for businesses around the globe who need increased speed and accuracy in their operations. Finally, we will look at some examples of what can be achieved with todays most advanced laser-cutting systems.

Get ready to uncover just what makes these amazing machines so special!

Exploring the Possibilities of Laser Cutting Technology

Laser cutting technology has revolutionized the manufacturing industry, allowing businesses to create intricate designs with precise accuracy and speed. With the ability to cut through a variety of materials such as wood, metal, plastic and paper, laser cutting machines offer a wide range of options for creating custom pieces or mass producing products.

From designing signs and logos to crafting furniture and jewelry, laser cutting technology is providing innovative solutions for businesses. The potential applications of this technology are vast; it can be used for industrial purposes such as creating automotive parts or medical equipment, as well as artistic endeavors like fashion design or sculpture making.

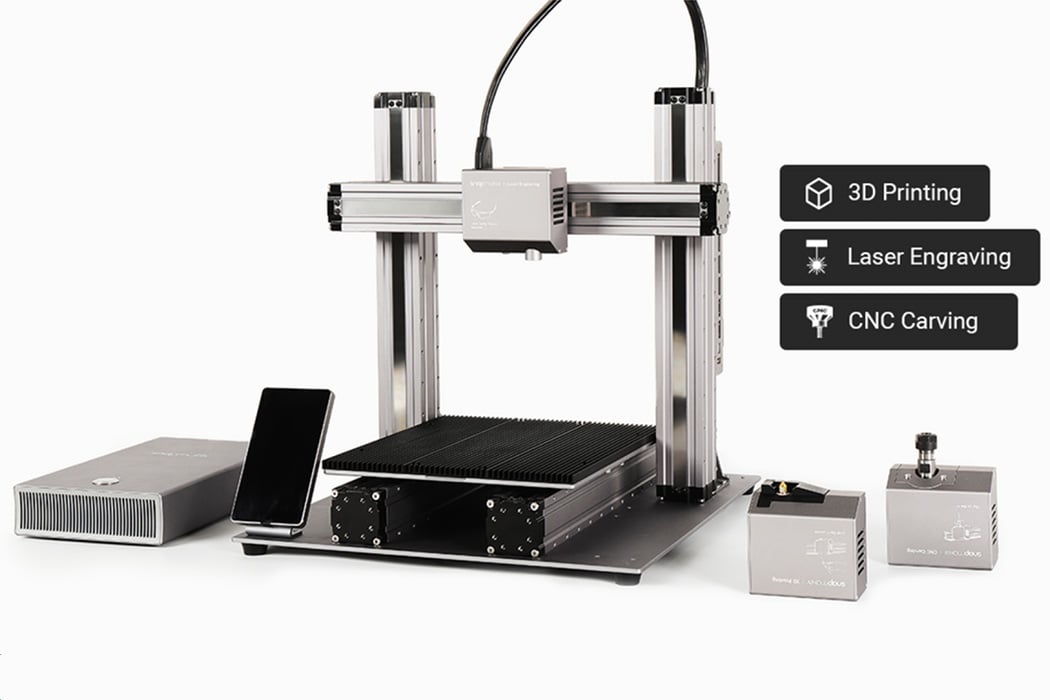

Thanks to its precision capabilities and cost effectiveness compared to traditional methods of fabrication, many creative artisans are now able to explore their ideas in ways that weren’t possible before. Laser cutting technology is also becoming more accessible due to recent advances in 3D printing technologies which make it easier than ever before for small scale operations or hobbyists alike to get started with laser-cutting projects at home! From its beginnings in research laboratories decades ago up until todays modern day uses – theres no doubt that laser-cutting machines have come a long way in terms of formulating what was once considered impossible into reality! The possibilities are endless when it comes unlocking the power behind these powerful machines – whether you want your own unique masterpiece crafted from scratch by hand or an entire production line created using automated systems – exploring all the avenues available within this exciting new field will certainly help you find something perfect for your needs!

Unlocking the Potential of Laser Cutters

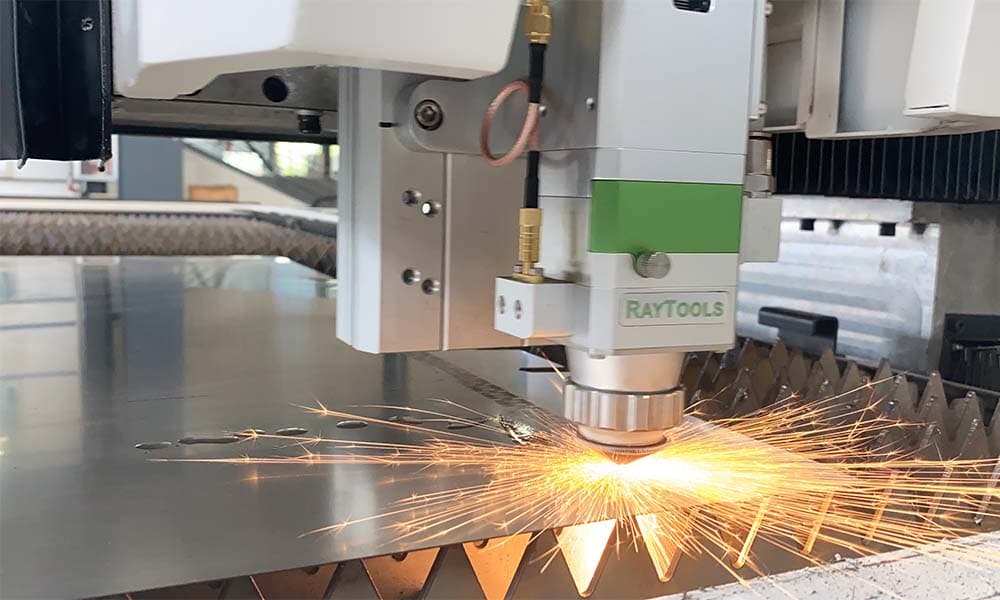

Laser cutters are revolutionizing the cutting edge of modern manufacturing. With their ability to precisely and quickly cut a wide range of materials, laser cutters open up a world of possibilities for manufacturers and designers alike.

From intricate patterns and shapes to larger scale production runs, laser cutting technology can do it all – faster, better, and more cost effectively than ever before. But what is truly remarkable about these machines is how much potential they have yet to unlock.

The key lies in pushing the limits of precision while still maintaining speed and accuracy across multiple materials types. Were seeing exciting advances with different lasers being able to accurately cut thicker materials or softer metals such as copper foil with extremely high detail at record speeds.

New software solutions enable even more complex designs which require only minimal manual adjustment compared to traditional methods like CNC routing or plasma cutting that would otherwise take hours upon hours for each design iteration. These improvements dont just extend beyond the physical side either; new AI-based monitoring systems mean operators have real-time feedback on performance metrics so they can tweak settings on the fly according to their needs as well as diagnose any issues that may arise during operation making sure that every job runs optimally no matter how big or small it might be.

By continuing to invest in research into unlocking the full potential of laser cutter technology we will see further increases in efficiency, innovation, safety & sustainability throughout all aspects of manufacturing from prototyping right through mass production – ensuring that anyone who uses them is always at The Cutting Edge!

An Introduction to Laser Cutting Machines

Laser cutting machines have revolutionized the way we produce and work with materials. From intricate designs to precise cuts, these powerful tools offer a wide range of capabilities that simply werent possible before.

But how do they work? This article will provide an introduction to laser cutting machines, explaining their components and applications in detail. At its core, a laser cutting machine uses a beam of light generated by lasers to cut or etch into surfaces with extreme accuracy.

Using sophisticated computer software programs, the machine is able to follow complex patterns with incredible precision. The result is sharp, clean-cut edges that require minimal post-processing or finishing work for many materials and geometries.

In addition to being used for industrial purposes such as fabrication and manufacturing processes, laser cutting technology has also become increasingly popular among hobbyists due to its versatility and affordability compared to traditional methods like saws or metalworking equipment. With only basic training required on operation safety protocols and maintenance procedures, anyone can learn how to use laser cutters for creative projects from jewelry making to woodworking — all without leaving home! The possibilities are endless when it comes to what one can make with a laser cutter: signs, prototypes for products testing out new ideas quickly; custom parts made exactly according your specifications; artistic pieces created in any shape you wish; plus much more! Laser cutters are also relatively easy maintain over time since there aren’t too many moving parts involved — just be sure you keep up regular cleaning sessions so that dirt doesn’t accumulate inside the system which could affect performance down the line if not taken care of properly.

Whether youre looking for something small scale like engraving personalized gifts or larger commercial projects requiring large numbers of identical parts produced at high speeds—laser cutters have got you covered! In short: this remarkable technology gives users access unprecedented levels of speed and accuracy when it comes creating anything imaginable—all within reach at home or business premises alike!

Conclusion

Laser Cutting Machines are an incredibly powerful tool, capable of performing complex and precise operations. They can be used to cut a variety of materials with accuracy and speed that is unmatched by other cutting methods.

With the ability to effectively handle intricate designs, Laser Cutting Machines provide businesses with the capacity to quickly make high-quality products at a fraction of the cost. This technology has revolutionized the manufacturing industry and continues to remain on the cutting edge for years to come.